Tokai Hit Stage Top Incubation System for 5% Co2 STXF-WELSX-SET

Incubation systems For well-plate, 35mm dish, 60mm dish, slide glass/chamber slide/chambered coverglass--Stage Top Incubator for Research

Offers precision temperature, humidity and CO2 control for cell culture on a microscope. Enables to conduct short and long term (more than 2 weeks) Time-Lapse Imaging.

By applying Real-time Sample Feedback Regulation, it can maintain an optimal cell culture environment which is as same as the conventional CO2 incubator.

With our variety of options, we can offer solutions for abundant applications, and leading the experiment to success.

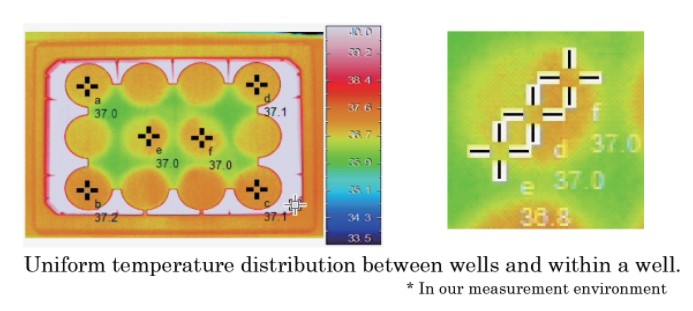

Accurate and uniform temperature control

TOKAI HIT Heating Quality

Tokai Hit's original Top Heater is proven to distribute heat uniformly within the Chamber

regardless of the type of vessels.

No interference by objective

With unique Top Heater Heating Time regulation, the bottom of Chamber is access-free for variety of objectives. (No metal plate at the bottom.)

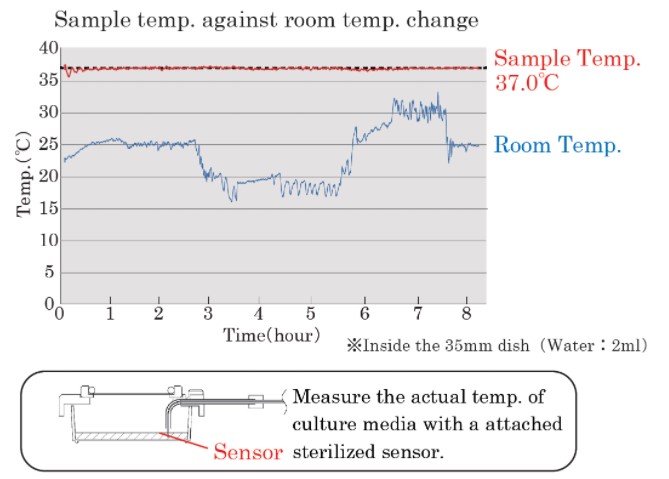

Real-time Sample Feedback Regulation

Sterilized temperature sensor and magnetic lids make it easy to measure

the temp. of culture media upon research needs.

The controller regulates the heater based on the sensor signal to keep sample at the target temp. accurately.

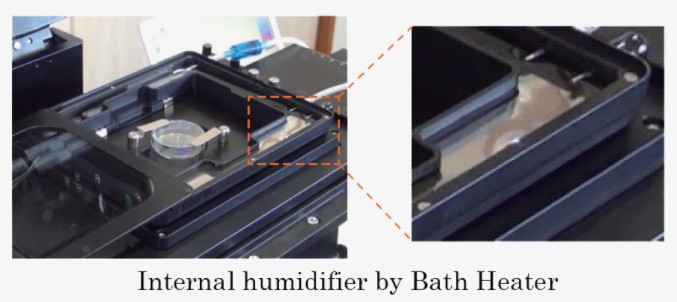

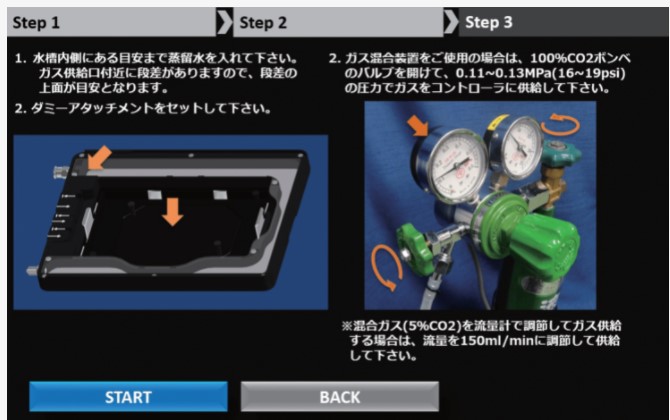

Keeps high-humidity over 95%

Keep the humidity level inside the chamber more than 95% by heating the distilled water in the Bath Unit.

The internal humidifier minimizes the change in concentration of media

by keeping the humidity inside the chamber.

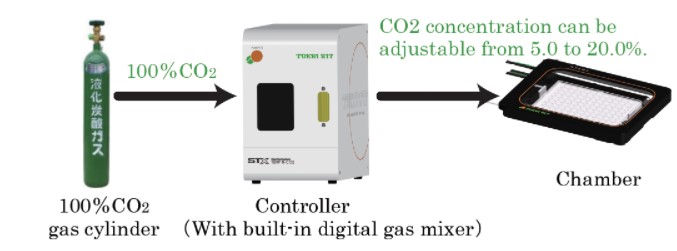

Stable CO2 environment

The controller mixes 100%CO2 gas and the surrounding air automatically. Stable gas concentration inside the Chamber is obtained by keep sending the mixed gas to the Chamber.

(※In case of controller with a built-in digital gas mixer)

Stress-Free Quality

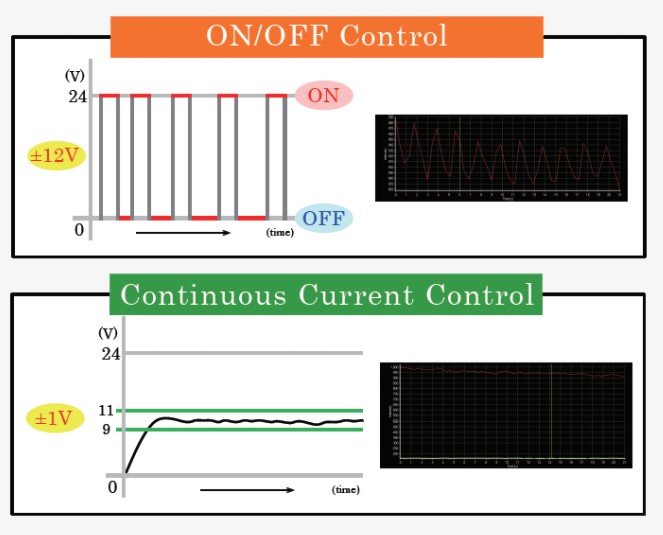

Prevent the focus drift

In addition to PID control, Continuous Current Control minimizes the focus drift generated by thermal expansion and it also prevents light intensity change compared to the conventional ON/OFF control.

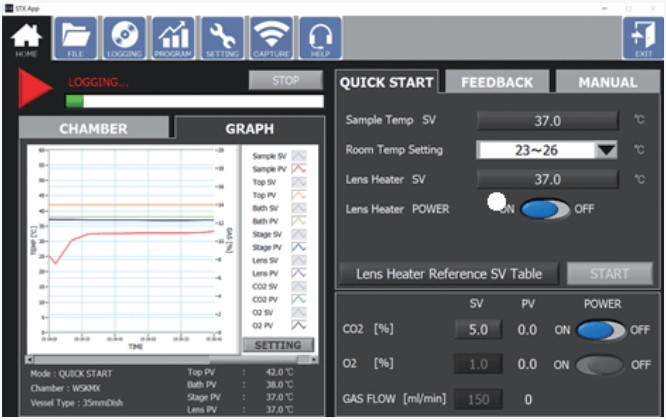

STX-APP (Software)

Simple operation of GUI will assist to visualize the preparation to setting and lead your cell culture to success.

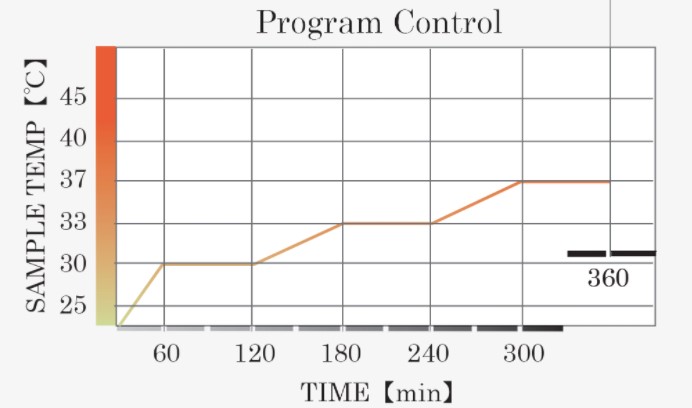

Programmable Control

The system includes the software to program temp. and CO2/O2 concentration

as this function allows to expand the variety of experiment.

Screen Capture

Captures the PC screen to transfer images to smart-phones and tablets.

Enables to see the image at home. *PC must be connected with internet.

Data Logging

Logs the temperature of each heaters, sample temperature and gas concentration

and saves the data in CSV format.

Specification

| STXG with built-in gas mixer | |

| Temperature control | PID control |

| Increments | 0.1℃ by digital switches |

| Setting method | Touch Panel or PC |

| SAMPLE TEMP | 30℃~40℃ |

| TOP HEATER | 10℃~65℃ |

| BATH HEATER | 10℃~50℃ |

| STAGE HEATER | 10℃~50℃ |

| LENS HEATER | 10℃~45℃ |

| Rise time | 10 minutes to reach 50℃ |

| Accuracy | Within ±0.3℃ at each heater surface(in our terms and conditions) |

| Sensor | Pt 100 |

| Humidification control | Forced humidification by heating Bath Unit |

| Condensation prevention | Top Heater equipped with glass heater |

| CO2 concentration range | N/A |

| Control method | Precision needle valve |

| Accuracy | Within±2% FS |

| Gas type | 5%CO2 |

| Input gas pressure | 0.1Mpa~0.15MPa |

| Output gas pressure | 75 ml/min~250 ml/min |

| Power source | 100 V~240 V AC ±10% 50/60Hz |

| Maximum power consumption | 90W |

*Controllable temp. setting range is from ambient +5c

All returns must be authorized by Spectra Services in order to insure proper credit and must be requested within 30 days of purchase. All returns are subject to a minimum 15% restocking charge. For returns not due to error on behalf of Spectra Services, the customer is responsible for all transportation fees related to the returned product. To ensure proper credit, each product return must include the following information:

- Customer name and address

- Purchase order number

- Spectra Services shipping order number

- Date of invoice

- Item number of returned item(s)

- Spectra Services return authorization number (RMA)

- Reason for return

Non-Returnable Goods

Unfortunately, Spectra Services is unable to accept the following returns at this time:

- Products not in completely resalable condition (including products with damaged, missing, or defaced labeling or packaging

- Chemicals, reagents, diagnostics, sterile, or any controlled products (unless products do not meet specification

- Laboratory apparatus or instruments that have been used or are without the original packaging, labeling and operating manuals

- Refrigerated products or other perishables

- Products which are not inventoried by Spectra Services and are not able to be returned to the manufacturer

- Products purchased on a special order

- Products not purchased from Spectra Services

- Products with an expired shelf life or an expiration date too short for resale

- Discontinued products

Spectra Services reserves the right to review this policy on a case-by-case basis.

Pre-Owned Products

Upon receipt of the pre-owned product(s), the customer has one week to evaluate the product to ensure it meets their expectations. If for some reason the customer decides to return the product, they may do so at any point during those seven (7) days for a full refund. No restocking fee will be assessed, however, the customer is responsible for the return shipping costs. Full credit will be issued upon receipt and inspection of the item(s) to ensure equipment was returned in the same condition it was initially shipped out in.

Important Information

All exchanges and returns require the completion of a Return Merchandise Authorization (RMA) form. Once completed, please return the merchandise immediately as the RMA number is only active for ten (10) days from the date of issuance.

Charges associated with returning items are the responsibility of the customer unless the item(s) arrived defective, damaged, or incorrect.

Spectra Services highly recommends that return packages be insured for full value and packaged securely to prevent shipping damage.

We're Here To Help

Your satisfaction is important to us! Use this form Contact Us to email us your questions about products, online orders, store experiences and more.

Order Questions:

If you need help or have any other questions concerning your orders, please click on the "Contact us" form above or call: 585-265-4320.

249 David Parkway

Ontario, NY 14519 US

Phone: 585-265-4320

I'm having a hard time searching for a product.

That's no problem. We're more than happy to assist you in your search. Give us a call, or drop us a line and let us know what you're looking for as best you can. We're always adding partner brands, and it's difficult to keep up with the thousands of products that get added to our lineup. Our sales specialists know our lineup best, and are most willing to help you find the solution(s) you need!

Why can't I complete my order online?

You most likely have one or more items in your shopping cart that are not priced. If you find that you can't complete an order, contact us via phone or email for further assistance.

What types of payments do you accept?

That's an easy one. We're very flexible when it comes to payment. Not only do we accept most major credit cards (Visa, Master Card, Discover, American Express), we also offer you the flexibility of paying by check, money order, wire transfers, and purchase orders. Work with any one of our sales specialists to figure out which method is best for you!

Do you charge sales tax?

Currently, we are authorized to collect sales tax in California, Connecticut, Florida, Indiana, Massachusetts, New Jersey, New York, Ohio, Pennsylvania, Texas and Washington. If we ship to any of these states, we are obligated to charge sales tax unless you provide us with a tax exempt certificate. You can either fax a copy of the certificate to our New York office (585.265.4374) or email it to ([email protected]).

Do you offer special pricing for government and educational entities?

Absolutely! Contact any one of our sales specialists to work out the details!

I just placed an order. Can I modify/cancel it?

We pride ourselves on providing you with a responsive and efficient buying experience. We are able to address your concerns in an accurate and timely fashion, and can usually ship your order within 24 hours of order placement. If you contact us within that window, we'll do our absolute best to accommodate your needs and concerns prior to shipment.

Do you accept international orders?

Of course! While we require a bank wire prior to shipment of the product on international orders, we assure you that the process is just as smooth for domestic orders. Take a look at our International Shipping Policy and contact us if we can assist.

Will I be charged for shipping?

Shipping charges will be added to your invoice unless you provide us with your UPS, DHL, or FedEx account number. For a more detailed insight into our shipping process, see our shipping information page.

I received a damaged shipment. What can I do?

Accidental damage during shipment can sometimes happen. When you take delivery of your freight, please inspect thoroughly for any visible damage to the outside of the shipping container before signing for it. If there are multiple pieces to the shipment, please account for all them. Should you find that any of the products are damaged or missing after receipt, contact us within three days to address the matter.

I'd like to make a return. How do I do that?

Take a look at our Return Policy, and then contact us to continue with the process. Let us know if you have any questions.

Can you guarantee pricing and availability?

While we attempt to list and provide you the most up-to-date pricing, we reserve the right to make changes. Additionally, we cannot guarantee that we will always have a product in stock, but we do our best to accommodate your needs. If you have questions regarding pricing or availability, please do not hesitate to ask.

Can you explain where you come up with the 'List Price,' please?

Our "List Price" represents the full retail price as suggested by the supplier or manufacturer, the price estimated based on comparable items offered elsewhere in the marketplace, a former price the item was offered for by Spectra Services, or the price estimated in accordance with industry standards. Please note that we do our best to provide accurate list prices, and that it may vary by geographic location.